Products

Tigerflex

Tigerflex

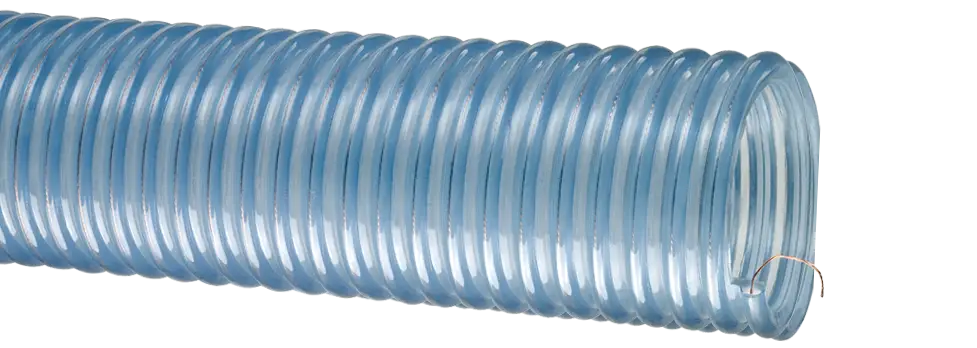

2001™ Series

Heavy-Duty Food Grade, Polyurethane Lined, Material Handling Hose with Grounding Wire

GENERAL APPLICATIONS

- Food grade material handling - heavy duty abrasive

- Pharmaceutical product transfer

- Plastic processing equipment

- Pneumatic conveying equipment

CONSTRUCTION

PVC cover with polyurethane liner, rigid PVC helix and grounding wire

SERVICE TEMPERATURE RANGE

-4°F (-20°C) to +150°F (+65°C)*

*Actual service temperature range is application dependent.

FEATURES AND ADVANTAGES

- Extra Thick Abrasion Resistant Polyurethane Liner – Designed for dry applications where severe abrasion is a factor. Provides for longer hose life and lower operating costs versus rubber or PVC hoses.

- Food Grade Materials – Hose Cover complies with applicable FDA(03) requirements. Hose Liner (Product Contact Surface) complies with applicable FDA(04) requirements and USDA(12) requirements.

- Grounding Wire – Multi-strand wire helps prevent the build-up of static electricity for added safety and to help keep material flowing smoothly. It’s embedded within the rigid helix to prevent contamination of transferred materials.

- Transparent Construction – “See-the-flow.” Allows for visual confirmation of material flow.

- Convoluted Outer Cover – Provides increased hose flexibility.

- Oil Resistant Polyurethane Liner – Resists most animal and petroleum based oils.

| Part Number | ID | OD | Working Pressure

(psi) |

Vacuum Rating Hg (in) |

Min. Bending Radius at 68°F (in) |

Standard Length (ft) |

Weight (lbs/ft) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (in) | (mm) | (in) | (mm) | at 68°F | at 104°F | at 68°F | at 104°F | ||||

| 2001–150 | 1 1/2 | 38.1 | 1.88 | 47.8 | 50 | 25 | Full | 28 | 6 | 60 | 0.48 |

| 2001–200 | 2 | 50.8 | 2.44 | 62.0 | 40 | 20 | Full | 28 | 7 | 60 | 0.67 |

| 2001–250 | 2 1/2 | 63.5 | 3.12 | 77.2 | 40 | 20 | Full | 28 | 8 | 60 | 0.92 |

| 2001–300 | 3 | 76.2 | 3.70 | 94.1 | 40 | 20 | Full | 28 | 9 | 60 | 1.35 |

| 2001–400 | 4 | 101.6 | 4.80 | 122.0 | 35 | 18 | Full | 28 | 15 | 60/20 | 2.17 |

| 2001–500 | 5 | 127.0 | 5.81 | 147.6 | 35 | 18 | 28 | 25 | 23 | 60/20 | 2.77 |

| 2001–600 | 6 | 152.4 | 6.93 | 176.0 | 30 | 15 | 28 | 25 | 26 | 60/20 | 3.90 |

| 2001–700 | 7 | 178.8 | 8.08 | 205.2 | 30 | 15 | 28 | 25 | 30 | 60/20 | 5.20 |

| 2001–800 | 8 | 203.2 | 9.28 | 235.8 | 30 | 15 | 28 | 25 | 36 | 20 | 6.65 |

NOTES:

• Service life may vary depending on operating conditions and type of material being conveyed.

CAUTION: Grounding wire is designed to help dissipate static charge when extracted and connected to ground. Hose is not to be used in combustible situations unless it has been determined by the end user the application is not sufficient to result in propagating brush discharge.

COMPLIANCES (click here for details)

BSE/TSE (02), FDA (03), Phthalate Free (10), RoHS (11), USDA (12)