Products

Tigerflex

Tigerflex

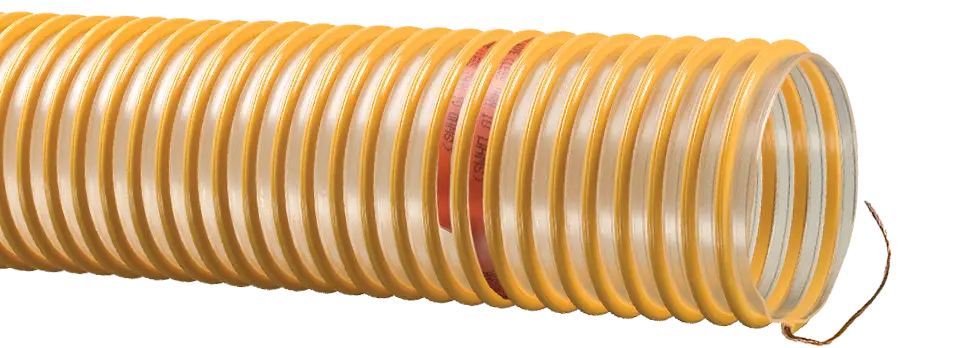

TV™ Series

Tigervapor™, Recovery Hose

GENERAL APPLICATIONS

- Tank truck vapor recovery

CONSTRUCTION

Polyurethane (TPU) tube with rigid PVC helix and embedded grounding wire

SERVICE TEMPERATURE RANGE

-40ºF (-40ºC) to +140ºF (+60ºC)*

*Actual service temperature range is application dependent.

FEATURES AND ADVANTAGES

- Lightweight – much lighter than conventional TPR/rubber hoses.

- Superior flexibility – especially in sub-zero weather!

- “See-through” construction – for visual confirmation if fuel backs up into the vapor recovery system.

- Grounding Wire – Durable multi-strand copper wire dissipates static electricity. Physically extract wire from the rigid helix and bond to the metal coupling (or by other means) to ground.+

- Easy Slide Helix – Rigid counter clockwise helix design protects hose tube from cover wear; allows hose to slide easily over rough surfaces.

- Biofuel Compatible – Revolutionary polyurethane compound! Specially designed to handle gasoline, ethanol**, diesel and biodiesel** vapors... and still keeps all the other great features and benefits!

- Non-permeable polyurethane construction – won’t swell or become stiff like conventional TPR/rubber hoses. Long life reduces operating costs.

| Part Number | ID | OD^ | Working Pressure

(psi) |

Vacuum Rating Hg (in) |

Min. Bending Radius at 68°F (in) |

Standard Length (ft) |

Weight (lbs/ft) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (in) | (mm) | (in) | (mm) | at 68°F | at 104°F | at 68°F | at 104°F | ||||

| TV202 | 2.02 | 51.3 | 2.46 | 62.5 | 17 | 6 | 21 | 12 | 3.0 | 100/60 | 0.51 |

| TV303 | 3.03 | 77.0 | 3.57 | 90.7 | 11 | 5 | 18 | 10 | 3.5 | 100/60 | 0.78 |

| TV404 | 4.04 | 102.6 | 4.61 | 117.1 | 9 | 4 | 13 | 8 | 4.5 | 100/60 | 1.10 |

NOTES:

• Service life may vary depending on operating conditions and type of material being conveyed.

** Meeting ASTM D5798, D4806 or D6751 criteria.

^ OD measured over helix.

‡ Based on Tigerflex force to bend test data @ 68°F.

ASSEMBLY SUGGESTIONS

Hose ID specifically designed for use with Kuriyama Couplings™. Refer to Hose Assembly Coupling Installation Suggestions and Technical Bulletin.